Have any questions?

+44 1234 567 890

Tobacco Journal International // Issue 1-2019

Article: emkon. retrofits the industry

The current issue of “Tobacco Journal International” features a detailed article about the challenges for our After-Sales Service, the Smart Service and the changes in the OTP sector.

Customers expect more flexibility and added-value services from emkon. The one way to tackle this is to be smarter with resources, the company said.

After-sales services have become increasingly important to customers, most of which are interested in how their capital is being invested, emkon. said. As capital expenditure shrinks, as a rule of thumb, companies begin to pay more attention to how they invest it. Currently, all company considerations in the decision-making process include conducting more tests and providing more detailed clarifications, according to the company. However, the largest obstacle for rebuilding machines is that during the time of the rebuild there is no production possible. “Even if a shift is possible, it is still accompanied with a significantly reduced production volume,” the company said.

CHANGES IN OTP SECTOR

Global market trends and changes in legislation have affected and shaped the operation practice in the area of rebuilds and spare parts. The OTP sector has grown and so has the need for reliable machinery. In the last couple of years, there has been a decline in consumption of ready-made cigarettes (RMC), the company informed TJI. Therefore, it is necessary for machine builders to develop novel machine types and smart technology, which has been a positive development for the company, emkon. said. The company developed its first OTP machine in 2009 and improved it to make the OTP pouch packer machine. “It is complicated for our customers to change from cigarette to OTP products because packaging products and materials are completely different. OTP products are simply more difficult to pack,” emkon. said.

“The biggest change that we have seen on the market is the volume size of pouches and containers, which have increased dramatically, especially MYO products. If you go back 8 to 10 years, the average package content was between 10 and 20 grammes per pouch. Today, we are talking about buckets instead of pouches when referring to volume, which can contain up to one kilogramme of rolling tobacco,” emkon. added. The company also said that more and more OTP manufacturers are producing all year round and, at the same time, less time is being set aside for regular maintenance of equipment. These conditions have forced the company to become even more efficient, emkon. explained. “Getting the job done quickly matters most alongside with reasonable prices and fast and direct delivery. Companies want experienced staff to follow up on service requests immediately and to come and adjust machinery onsite on short notice.” The availability of spare parts poses another issue for customers, emkon. said. “Customers prefer to have a minimal amount of parts in stock at their premises and rather have a hub somewhere in between their company and their supplier’s location.”

Gallery ( 4 photos)

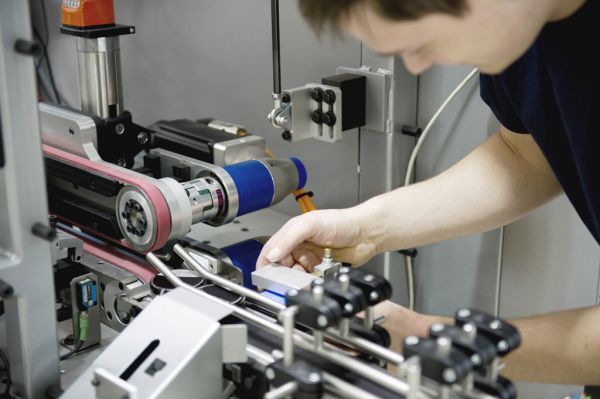

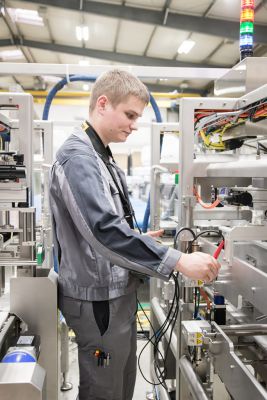

emkon. packaging machines: Requirements related to service and maintenance are becoming more complex.

SMART SERVICE

Digital solutions for after sales services are becoming very popular among clients. With emkon.’s smart support system, customers are able to download an app onto their mobile phones or tablets and contact emkon.’s first level of service support directly. This app allows the customer to send a live video, from any EU country, to the emkon’s service department, so that the company is able to see and hear what is wrong with the customer’s machine.

[Further informations about the emkon. SMART SUPPORT Service App]

In the rebuilds and retrofits segment, emkon. is participating in a project, called Retrosmart, which is intended to increase machinery availability by retrofitting hard- and software into older machinery to make it ready for the digital age.

[Further informations about retrosmart]

The specifications of the future products dictate whether it is possible to rebuild a machine or whether or not there is a need to design a new unit. emkon. said it currently builds very flexible machines, so various changeovers can be done with format kits. But even these machines have their limitations. Due to legislation, the freedom to develop new packaging designs is limited, the company said. “TPD1 and TPD2 is just the beginning. Plain packing will be introduced to more and more countries in Europe. Furthermore, next generation products will be regulated more strictly in the near future,” emkon. said.

SOURCING SPARE PARTS IN A NEW WAY

As costs and delivery times from sub-suppliers continue to increase, emkon. has had to make adjustments to its planning process in such a way that its customers are not impacted by these changes, the company told TJI. “A lot of special parts suppliers have major delivery problems and delays, and even sourcing of raw materials and sub-assemblies is becoming a challenge,” emkon. explained. “We function as a buffer in this process and we try to plan regular maintenance on equipment in order not to affect the customer’s schedule. “Even though the tobacco business is quite a compact business, there is a constant turnover coming on spare parts from long-term business partners,” reports emkon. As a traditional tobacco business of RMC is mainly conservative and not very open to new products any more because of TPD restrictions in Europe, there is still a great demand for rebuilds due to changes such as pack content change, format change, etc. On the one hand that makes machine building manufacturers, like emkon., think more openly about the future and prepare for it. Alternative products like e-cigarettes, heat-notburn products and other smokeless tobacco products will keep machine manufacturers busy designing solutions for all possible challenges to come in this segment.

Do you need to overhaul old packaging machines and like to fit them for future requirements? Please feel free to contact our Mr. Mann. He is your contact in case of service and maintenance work. He will be pleased to find with you the best solution for your production.

Your contacts

emkon. Systemtechnik,

Projektmanagement GmbH

Björn Fichtler

Sales Manager Tobacco Division

Phone.: +49 4236 9436 197

Email: bjoern.fichtler@emkon-automation.com