Have any questions?

+44 1234 567 890

Packing of unfilled coffee capsules

Capsule packer EMKON CAPSULA

The request of our customer was a fully automatic machine solution that packs unfilled coffee capsules and combines high process reliability with flexibility. Almost 6 months later, we had successfully finished the challenge with our new developed machine emkon. CAPSULA. The first machine already produces in the main plant of our customer in Switzerland. A second machine is about to be delivered and subsequent orders are already under discussion. Also, further producers of thermoforming machines are made aware of this new technology.

Our capsule packer emkon. CAPSULA on YouTube:

The machine can run three different capsule sizes (Ø 37/45/54 mm) and is able to handle plastic capsules as well as recyclable or compostable capsules. Any other capsule formats/sizes are adaptable. A much higher packing density of the capsules in the shipping case might be quite an advantage of our machine. This saves money and contributes to fewer truck traffic on the streets.

It’s all about accuracy

The overall task of our emkon. CAPSULA includes the admission of the coffee capsules from a thermoforming machine (M92 HD with downstreamed hole punching unit 4hole by company Gabler), the correct count of the in strands incoming capsules and the final put into prepared bag-in-box cartons according to the packing schemes.

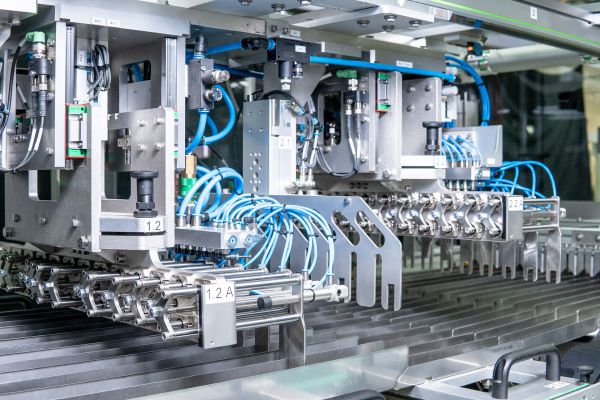

The capsule strands are horizontally transferred in rows out of a Gabler stacking basket to the emkon. CAPSULA. An active guided transfer unit leads the capsules to an endless cord. A particular feature: The single strands of the capsule basket are not always containing the same number of capsules. Due to that, we combine the single strands to 14 parallel endless strands which are fed simultaneously to the counting unit. The counted capsules are pushed into a tact chain. Two sensors are monitoring the minimum and maximum filling position of each single strand. The next station is the grouping table: Previously discharged or missing capsule strands are automatically compensated by the system through the interaction of servo technology and further pneumatic transfer units on the grouping table. This always ensures that only the complete number of capsule strands is inserted into the bag-in-box carton by the product gripper.

Gallery (7 photos)

Packing of unfilled coffee capsules with the emkon. CAPSULA

Process-reliable advantages due to modular design

With the simultaneous multilane processing of the coffee capsules, we achieve slower movements on the individual modules. This results in significantly less interferences from capsule twist or clamp in the transport with a performance from up to 3.000 capsules/minute – higher performances are possible! The modules product admission and the counting unit with transport, provision and the packaging module are work independently of each other. “The customer confirms that the efficiency and the reliability has increased significantly, compared to the old system used. Our modular design enables us to connect easily other thermoforming machines e. g. Illig machines”, adds Ralf Köster, Sales Manager at emkon.

In the process, single capsule rows or entire strands can be discharged at various points in the machine, for example for quality control or to remove damaged capsules. This possibility exists also directly behind the stacking basket if certain rows from the upstream process must be rejected because, for example, a forming tool is not at the correct operation temperature.

Our visualization “tracks” NIO strands on the control panel in real time and highlights them in color. A counting mechanism keeps the operator informed about the filling level in the case and the number of packed coffee capsules.

A further benefit is the small number of format parts. This allows a very quick changeover to a different capsule format. Quick-change devices are mainly used to change between the capsule sizes Ø 37/45/54 mm. The tact chain and the grouping table can even independently take all capsule shapes and process them without format chain.

Experienced technology provider

Coffee capsules continue to enjoy great popularity worldwide. They satisfy the need of consumers to prepare their coffee quickly, easily and in portions. This unbroken trend is causing manufacturers and producers to become increasingly automated and flexible in production.

With our expertise in this field, we are a reliable partner for the industry and our customers. Next to this emkon. CAPSULA machine solution for our Swiss customer, we were recently able to successfully convince Tchibo GmbH from Hamburg of our packaging concept for their own Qbo capsules and have developed and delivered our complete machine solution, the emkon. CAPSOLUTION.

*Performance data are dependent on the actual product properties