Have any questions?

+44 1234 567 890

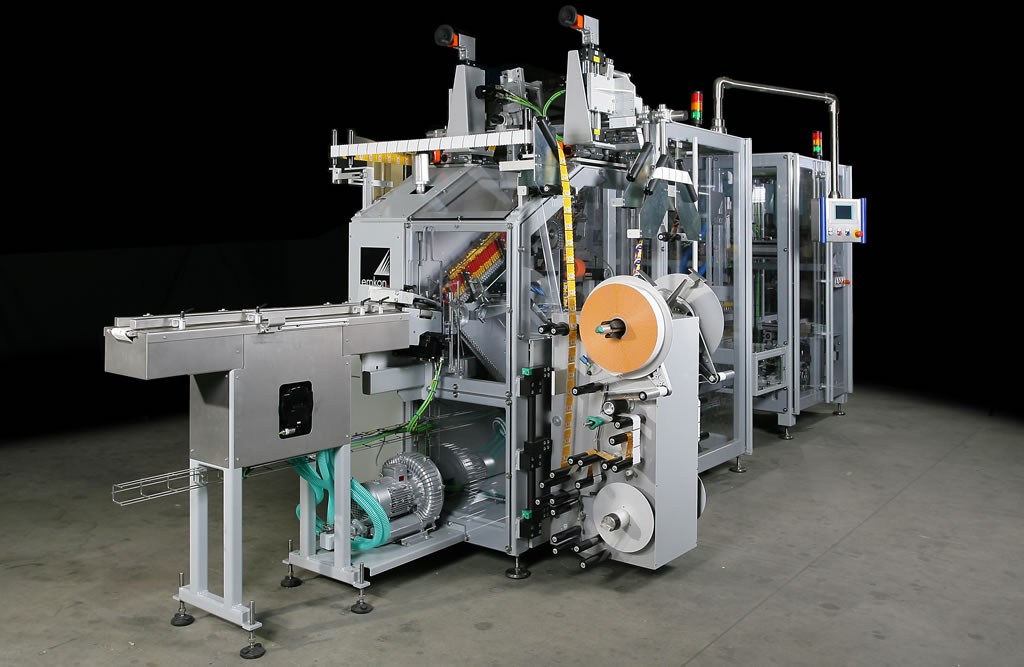

EMKON MULTIPACK

CASE STUDY: MULTIPACK BAHLSEN

CUSTOMER:

Bahlsen GmbH & Co. KG

Hannover

PRODUCT:

Leibniz PiCK UP!

PACKAGING SOLUTION of emkon.:

EMKON MULTIPACK

CUSTOMER SINCE

2003

CUSTOMER REQUIREMENT:

- Bundling / labeling of PiCK UP!s packed into tubular bags in various bundle sizes

- Expansion of production capacity

- Performance increase

- Optimization of packaging through precise positioning of the label perforation

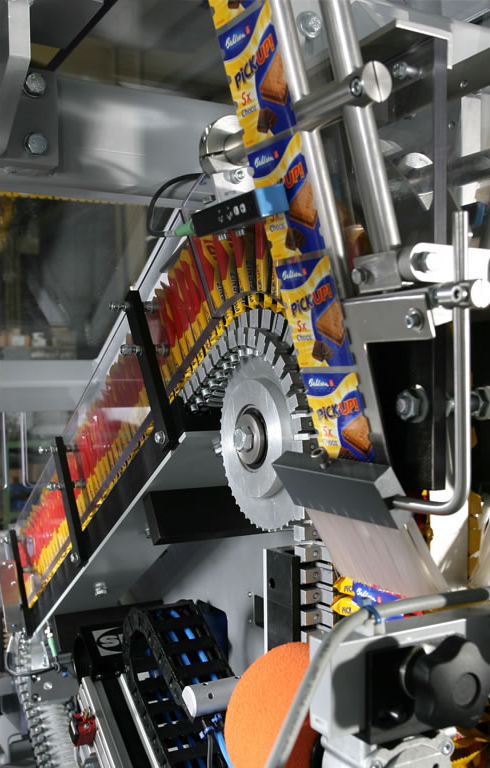

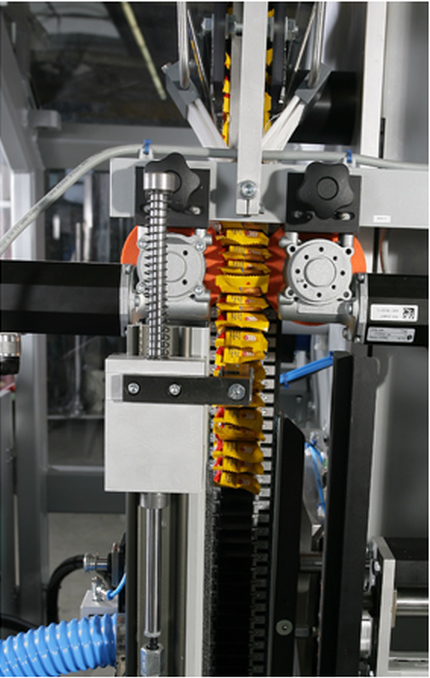

- Gentle product handling of the delicate chocolate and biscuit product even at high speed

emkon. SOLUTION:

With a speed of 600 products / min at the infeed the pre-packed, single PiCK UP!s are grouped by the emkon. MULTIPACK. Through double-sided labeling multipacks of 3 - 12 bundles can be made. A pocket chain ensures the accurate distance and the gentle handling of the single products. Tray packers, also built by emkon., and installed downstream of the emkon. MULTIPACK places the multipacks into shipping cases.

CONCRETE CUSTOMER BENEFITS:

- Cost savings: by using double-sided labeling to make multipacks additional packaging material is reduced

- Flexibility: due to the modularity of the machine market-related product adaptations are possible at any time

- End consumer satisfaction: exact perforation guarantees easy handling

- High production speed

- High product quality

THE emkon. MULTIPACK IN THE VIDEO

INTERVIEW:

We love bundles

FACTS:

MODULAR DESIGN

Easy operation

Short changeover times

Very small footprint

SAVINGS OF PACKAGING MATERIALS

One perforated label for the entire pack

HIGH PRODUCTION SPEED

600 products / minute at infeed

EASY FORMAT CHANGE

Without additional use of tools

Minimal time requirement

HIGH FLEXIBILITY

Packages of 3 – 12 individual products

Simple and quick change of material reel

EASY EXPANDABILITY

Effortless integration with existing machines

Simple combination with tray packers

Additional CASE STUDIES

emkon.

SMARTFOLD

emkon.

BISCUIT DEPOSITOR

emkon.

SURROUNDER

emkon.

FLEXBAG