Have any questions?

+44 1234 567 890

emkon. BISCUIT DEPOSITOR

CASE STUDY: BISCUIT DEPOSITOR

CUSTOMER:

International Food Company

PRODUCT:

Combination of chocolate bar and biscuits

PACKAGING SOLUTION of emkon.:

emkon. BISCUIT DEPOSITOR

CUSTOMER REQUIREMENT:

- Particularly high requirements in regards to precision and reliability.

- Joint optimal product development.

- Reliable, equally high-quality processing of biscuits and chocolate.

- Precise and product-friendly handling of small biscuits of different varieties.

- Automatic completeness checks of biscuit placement.

emkon. SOLUTION:

Speed, reliability and precision at the highest level – 3600 times per minute – that is the emkon. BISCUIT DEPOSTIOR

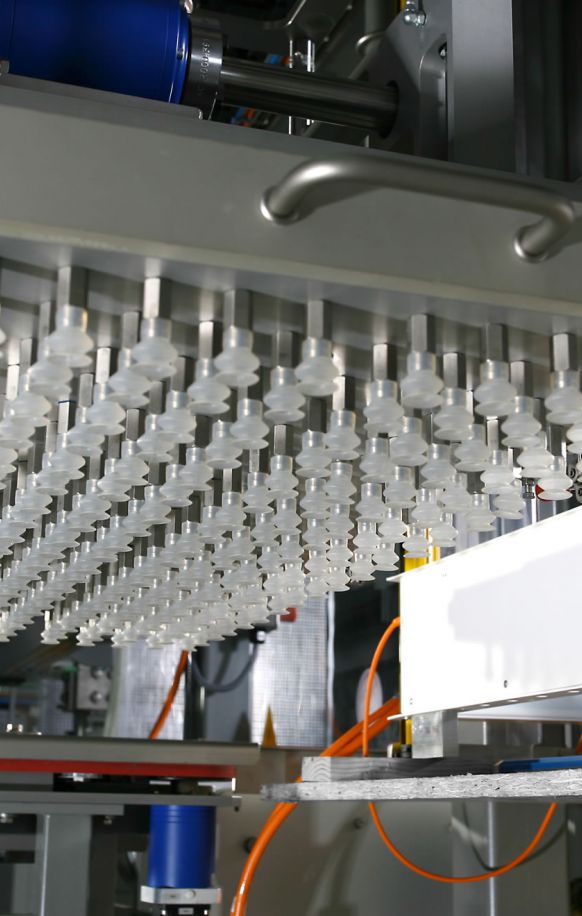

The emkon. BISCUIT DEPOSITOR combines the latest robot with camera- and linear transfer technology and sets new standards in fast and reliable product handling. 18 times per minute the Pick & Place unit of the emkon. BISCUIT DEPOSITOR with its 200 vacuum cups transfers the small biscuits precisely and reliably onto the still liquid chocolate. In case a biscuit is missing in the transport form, it will be detected by the camera system. A pick robot installed downstream fills the detected gaps and ensures a 100% placement of biscuits on all chocolate bars.

CONCRETE CUSTOMER BENEFITS:

- Cost saving: one machine to handle all different biscuit varieties

- Product quality: combined technology application guarantees consistent high quality

- Flexibility: the Pick & Place vacuum system handles various formations and product sizes

THE emkon. BISCUIT DEPOSITOR IN THE VIDEO

FACTS

MODULAR DESIGN

Easy operation

Easy cleaning and maintenance

Small footprint

DIVERSITY OF VARIETIES

Handling of different biscuit varieties

Flexible amount of workable products is adjustable

Variable product formations and sizes are adjustable

FLEXIBLE VACUUM SUCTION PLATE

200 Vacuum Pick & Place suction heads

Individual tracks can be disabled

Particularly gentle product handling

Quick release system for changeover and cleaning

Independent, adaptable system – no central vacuum system needed

EASY MAINTENANCE

Automatic maintenance position for suction plate

Good accessibility of maintenance area

Easy module cleaning

Safety-relevant blocking or locking „LOTO“

CONTROLL SYSTEMS

Automatic completeness check by camera

Guaranteed 100% product completeness via integrated Pick & Place robot

Additional control device for transport molds

Additional CASE STUDIES

emkon.

SMARTFOLD

emkon.

MULTIPACK

emkon.

SURROUNDER

emkon.

FLEXBAG